AEP BIOMATIC GREASE INTERCEPTOR

AEP Biomatic Grease Interceptor incorporates hydro-dynamics principle whereby the air release provides small amount of buoyancy pressure to the FOG contents in the separation chamber by way of regulating the internal running water level of the grease interceptor. The water generated rush air which accelerates the separation process of FOG, resulting it to rise rapidly to the surface of the water in the separation chamber. The rising air bubbles literally pull the globules to the top of the water quickly and leaving the clean water below.

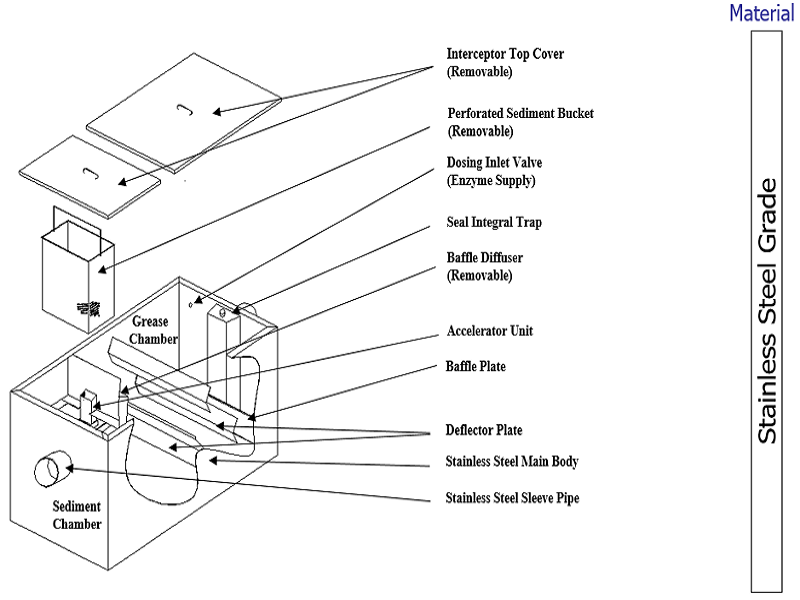

AEP BIOMATIC GREASE INTERCEPTOR COMPONENTS

Functionality of AEP Biomatic Grease Interceptor

Removal of Solids

Removal of Solids

Wastewater contains fats, oil & grease (FOG) enters where solid sediment is strained for removal.

Wastewater contains fats, oil & grease (FOG) enters where solid sediment is strained for removal.

Grease Dispersion Separation

Grease Dispersion Separation

FOG are dispersed to avoid solidification & separated by generation of

optimum grease rise rate.

FOG are dispersed to avoid solidification & separated by generation of

optimum grease rise rate.

Fats, Oil & Grease Digestion Through Natural Process*

Fats, Oil & Grease Digestion Through Natural Process*

The microbes rapidly digest soluble wastes converting it into water and carbon dioxide gas.

The microbes rapidly digest soluble wastes converting it into water and carbon dioxide gas.

Eliminates Odors Naturally*

Eliminates Odors Naturally*

During the FOG breakdown process by the cultured microbes, it releases natural fragrance.

During the FOG breakdown process by the cultured microbes, it releases natural fragrance.

Filtered Clean Water

Filtered Clean Water

The treated clean water continues to flow from the outlet to the sewerage.

The treated clean water continues to flow from the outlet to the sewerage.

Key Features |

|

|

Oil & grease removal > 98% |

|

Wide operating efficiency range |

|

Integrated auto dosing function |

|

Maintenance friendly design |

Benefits |

|

|

Compliance to federal regulations |

|

No energy consumption |

|

Treated with no chemical process |

|

Constant effluent discharge quality |

|

Compact size |

|

Removable for relocation |

Application |

||

|

All kinds of FOG's wastewater | |

|

Commercial centres | |

|

Residential areas | |

|

Retail F&B outlets | |

|

Food processing industry | |

|

Cafeteria & food courts | |

|

Wet markets | |

|

|